Basic Principles

– **High Temperature Short Time (HTST) Treatment**: Milk is rapidly heated to 135-150°C and held at this temperature for a few seconds before being quickly cooled to ambient temperature.

– **Complete Sterilization**: This treatment method effectively kills all microorganisms in milk, including bacteria, viruses, yeasts, and molds, ensuring the product meets commercial sterility standards.

Heating methods:

– **Direct heating**: Steam is directly injected into the milk, suitable for high-end products or those with high flavor requirements.

– **Indirect heating**: Heat is transferred to the milk through a heat exchanger, suitable for large-scale production and featuring high operational efficiency.

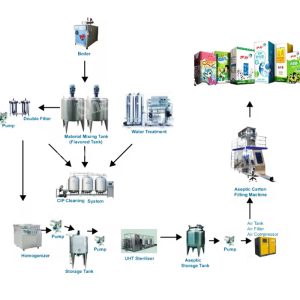

Process Flow

1. **Raw Milk Pretreatment**: Filter, cool and standardize the raw milk to ensure it reaches the ideal hygiene and composition state.

2. **Ultra-high Temperature Sterilization**: Heat the milk to 135-150℃ in a sealed pipe for a few seconds and then rapidly cool it.

3. **Aseptic Filling**: Use aseptic filling technology to fill the sterilized milk into Tetra Pak packaging, ensuring the product can be stored at room temperature for a long time.

Technical advantages

– **Extended shelf life**: Milk processed by UHT can be stored at room temperature for several months without refrigeration.

– **Energy conservation and environmental protection**: Advanced technologies, such as the “one-step” process, are adopted to reduce energy consumption and carbon emissions, and lower production costs.

– **High-efficiency production**: Multiple production steps are integrated to reduce equipment floor space and maintenance work, and enhance production efficiency.

Product Features

– **Nutrient Retention**: Although high-temperature processing can have some impact on certain heat-sensitive vitamins and flavor components, UHT technology can complete sterilization in a short time, maximizing the retention of milk’s nutritional components.

– **Flavor Impact**: Compared with pasteurized milk, the flavor of UHT milk may be somewhat different, but it performs better in terms of taste and stability.

In conclusion, the ultra-high temperature sterilization technology used in Tetra Pak milk production lines is an efficient, safe, and energy-saving and environmentally friendly sterilization process, which can meet the modern consumers’ demands for long shelf life and high-quality milk.